Contact Us

![]() Home Page > Product Center > License Plate Recognition Unmanned System

Home Page > Product Center > License Plate Recognition Unmanned System

Product Details

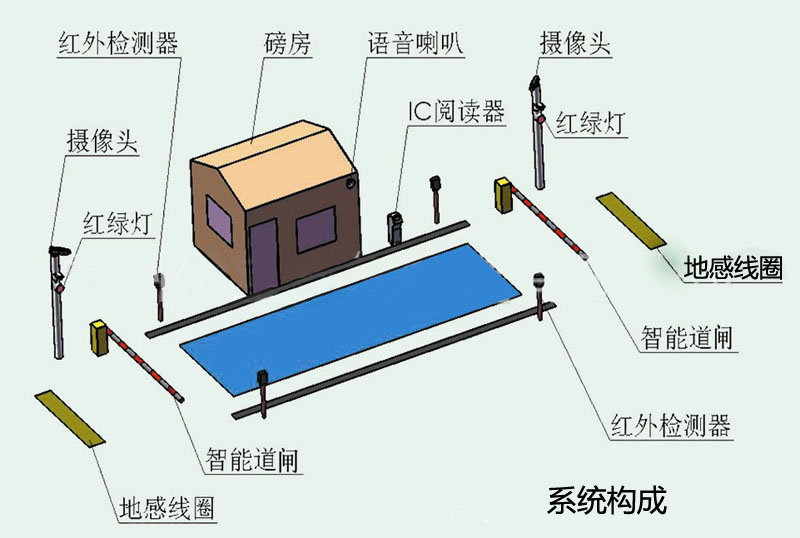

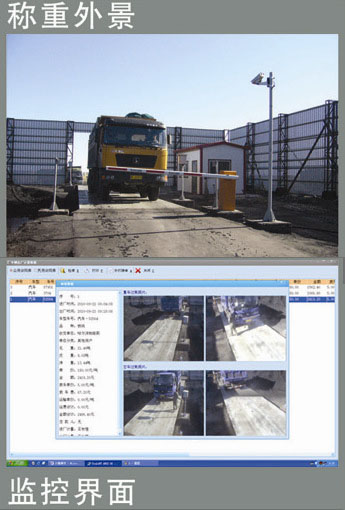

It is an anti cheating management for the transportation vehicles entering and exiting the measurement of bulk materials as the main production raw materials and sales products for factories and mining enterprises in the procurement, sales, warehousing and other business of materials. It refers to the rapid, accurate, safe, stable and reliable completion of the measurement process without human intervention, achieving fully automated management of information collection during the measurement process. The system monitors the entire measurement process through rigorous computer flow design to prevent human loopholes. Using this system can reduce production costs, eliminate fraudulent behavior, enhance management efforts, and improve the level of enterprise informatization.

workflow

1. When the vehicle enters the weighbridge, it is triggered to collect vehicle information through coils, video, or infrared radiation.

2. The signal collector detects the signal and gives instructions to the camera to trigger the capture of the license plate.

3. Unmanned weighing scales with license plate recognition automatically capture images of vehicles and identify the license plate identification number, and then retrieve the vehicle category through a database search.

4. The system automatically generates a form for weighing weight, license plate number, vehicle model, and license plate image, and saves the information for easy access and printing at any time.

5. After getting off the weighing scale and entering the weighing instrument, the system records the departure time of the vehicle.

Features

01. The entire system can achieve unmanned or driver self-service weighing;

02. A single weighing scale can support two unmanned measurement modes: one-way or two-way;

03. Detected that the vehicle automatically opens the barrier gate when entering the system, and the traffic lights turn from green to red;

04. Automatically enter basic vehicle information through the card swiping system;

05. Image acquisition and dynamic video recording of weighing process;

06. During the weighing process, the driver is guided by voice and LED screen to complete the entire process;

07. Support on-site printing, automatic printing and paper cutting of receipts, and the system can prompt the remaining quantity of printing paper, making it convenient for inspectors to replace them in a timely manner;

08. After the vehicle is weighed, the voice and LED screen prompt the vehicle to enter the next business process. After the vehicle is weighed, the barrier gate is lowered and the traffic lights turn green;

09. The system supports peripherals such as infrared gratings, cameras, RFID readers, traffic lights, barriers, LED screens, voice systems, self-service terminals, etc;

10. Introduce RFID and IC card dual card integration, with IC card as the transmission medium for easy sampling and confirmation of shipping and receiving;

11. Introduce unmanned self-service terminals, which can be used for self-service card issuance, information input, and other operations to assist drivers in measuring;

12. The system supports three unmanned modes: on-site unmanned operation, driver self-service weighing, and remote centralized measurement;

13. The system supports unmanned sampling systems and reserves interfaces (interface modules are required);

14. Reserved interface between the system and the rapid loading system (interface module required);