Contact Us

![]() Home Page > Product Center > Weighing type level gauge system

Home Page > Product Center > Weighing type level gauge system

System introduction

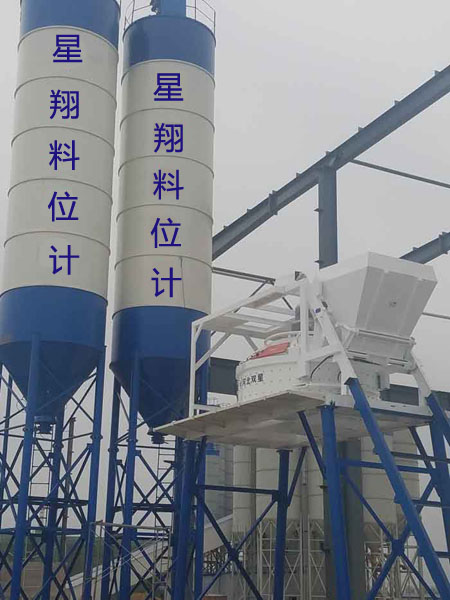

Shandong Xingxiang Automation Weighing Equipment Co., Ltd. has leveraged its technological advantages in the weighing field and combined them with the problems encountered in the management of mixing stations to develop this system. This system enables the quantity in the material tank to be scientifically and intuitively detected, eliminating concerns about safety accidents such as material silos being overfilled.

The Xingxiang weighing-type material level weighing system is easy to install, requiring no tank access and direct installation with support legs. Once installed and calibrated, no further operation is needed for subsequent use. Each tank is equipped with a gauge, providing real-time display of the remaining amount inside the tank, just like placing the tank on a scale. When the material reaches the preset upper limit, it will automatically trigger a light alarm at the inlet, prompting the driver to stop loading, eliminating concerns about tank overflow. It fully complies with the requirements of the Technical Specification for Green Production and Management of Ready-Mixed Concrete (JGJ/T 328-2014).

It strictly controls the upper limit of tank capacity, leaving a certain space at the top of the tank. Therefore, the dust collector of the tank has good performance, long service life, and saves maintenance costs.

The weighing unit does not come into contact with the material and has no moving parts, so it has an exceptionally long lifespan and incurs no operating costs. We promise to provide technical guidance for installation in the early stage and follow-up visits by dedicated personnel in the later stage. If you are not satisfied within two months of purchase and use, you can return the product for a full refund. After satisfaction, the main components come with a five-year warranty. Our service aim is to ensure customer satisfaction.

This system is currently a practical and reliable material level detection system for mixing stations. It is more reliable than the commonly used system calculation and display methods. Because system calculation requires manual input, there is a possibility of human error. System calculation also accumulates systematic errors, which will accumulate more and more, and may explode someday.

Since the launch of this system, customers have reported that it is very easy to use, and many customers have stated that they cannot do without our material level indicator in production management. We hope that you can use it soon and become a beneficiary of applying this system.