Contact Us

![]() Home Page > Product Center > Weighing type level gauge sensor

Home Page > Product Center > Weighing type level gauge sensor

System Introduction

Currently, the measurement of powder material silos mostly relies on the primitive method of combining knocking the tank and weighing, which requires a lot of manpower and cannot obtain accurate information about the material stored in the silo. This method is prone to material breaks during production, affecting production; during the feeding process, it is easy to cause silo explosions and overflows, which not only pollutes the environment but also easily damages the dust removal equipment on the silo roof. This product is attached to the leg of the silo without changing its structure, and installation does not require production downtime. It is durable and maintenance-free, with a measurement accuracy generally up to ±3% of the silo's maximum capacity, perfectly solving the above problems.

System Features

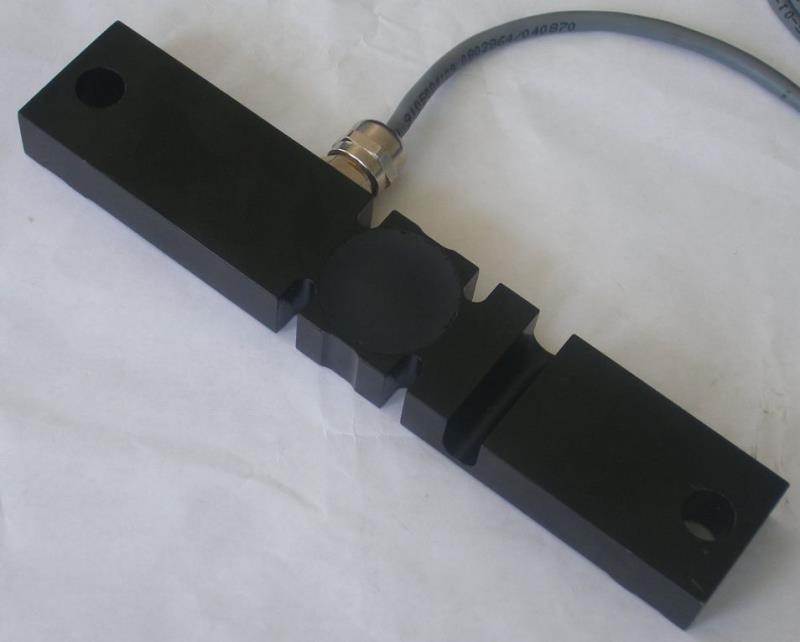

1. Install one XXLWJ8000 detection terminal in each warehouse to display the material weight in real time.

2. Each production line is equipped with a touchscreen display box, which utilizes numbers and bar charts to display the current material level, supporting up to 16 bins.

3. Real-time material level information can be viewed through the mobile APP.

4. It can be connected to the station's local area network, allowing every authorized office computer within the station to view real-time material level information.

5. It can be integrated into the production computer, allowing real-time display of material level information on the production software.

6. An optional high-level alarm indicator can be equipped to prevent occurrences of material shortages and overfilling in powder material silos.

7. An optional automatic dust removal control system can be installed to prevent accidental opening of the pressure relief valve due to failure to activate the dust removal function, thereby avoiding environmental pollution.

8. It can be integrated with enterprise ERP (BGM Enterprise Integrated Management System).

Technical specifications

1. Power supply voltage of the central control box: AC220V.

2. Power supply: DC24V.

3. Number of measurement bins: Each set can accommodate up to 16 bins.

4. Number of sensors per bin: 4.

5. Application scope: All steel-supported legged silos.

6. Measurement range: 0 to 3000 tons.

7. Operating conditions: ambient temperature -20~50℃, no corrosive gas.