Contact Us

![]() Home Page > Product Center > Internet of Things transaction weighing software

Home Page > Product Center > Internet of Things transaction weighing software

Characteristic

◆ Pioneering remote transmission without broadband data

◆ Wireless remote centralized management of weighing equipment

◆ Local area network or Internet plus networking

◆ Weighing monitoring and capture

◆ Public pound billing

◆ One machine with dual scales

◆ Weighing data is synchronized between the Hengqibao APP and the computer web page

◆ Electronic wallet function. Each user can purchase products with individual pricing and pay on a per-use basis

◆ Support contract plan quantity, with the buyer making a one-time payment and shipments being made in batches

◆Automatic weighing, and saving the weighing results

◆ Can be connected to counting and pricing scales such as the Purison, for automatic conversion

◆ Can independently design weighing interfaces and formula calculations

◆ Support inventory inquiry

◆ Multiple permission design, scientific management

◆ The format of the weight note can be designed independently

◆ Supports printing barcodes, QR codes, and company logos

◆ Two weighing sheet design modes are available

◆ Autonomous design of QR code and barcode printing formats

◆ Supports at least 200 mainstream weighing instruments

◆ Remote control alarm and remote reminder

◆ Scheduled email push of reports

◆ Support quick input for associated tables

◆ Weighing data is displayed on an external LED or digital tube screen

◆ The interface is open, allowing integration with various MIS systems such as SAP, Oracle database, UFIDA, Kingdee, and Inspur ERP

◆ Customized development can be provided according to user requirements

Scope of application

This system is applicable to various enterprises such as coal mines, ranches, ports and docks, coal washing plants, coking plants, steel plants, cement plants, stone processing plants, mixing stations, environmental protection stations, vehicle management offices, chemical plants, grain processing, and purchasing.

Basic functions

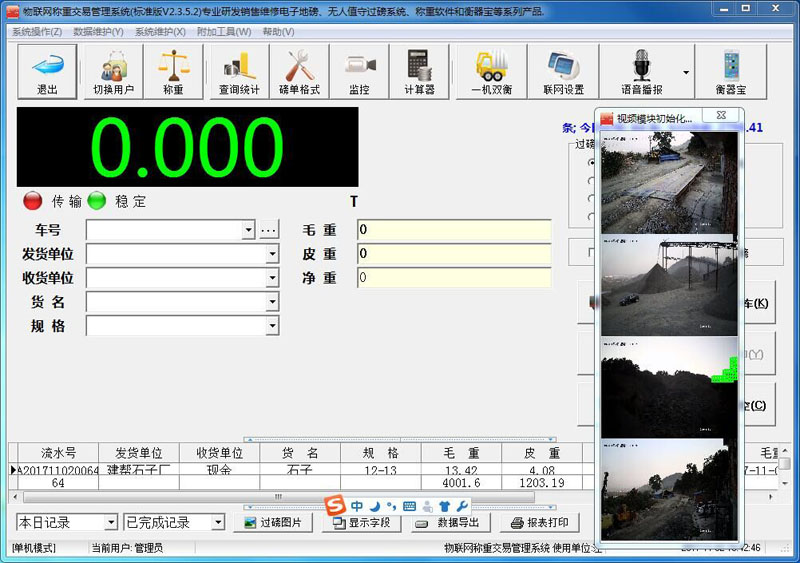

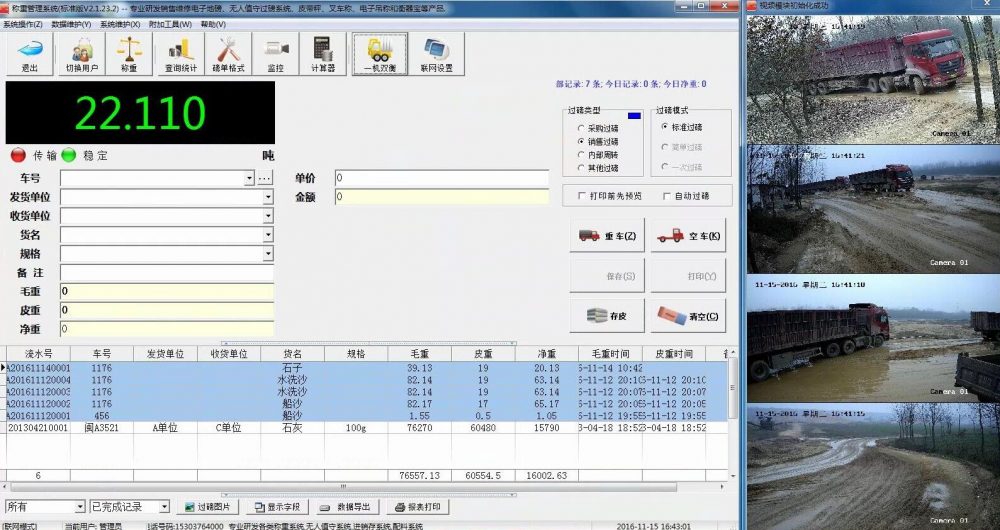

1. Data collection. Weighing data is automatically collected and cannot be manually entered, thus eliminating the possibility of falsified weighing data.

2. Universal compatibility. The weighing data acquisition is synchronized with the weighing instrument, compatible with over 200 weighing instruments on the market. If it cannot be interfaced, a protocol can be customized for free.

3. Print control. There is a strict control function for the number of prints, and reprints require authorization from the leader.

4. Access control. It has strict access control functions to prevent operators from operating beyond their authorized scope.

5. Intelligent association and filtering. The software automatically records the weighed vehicle number. When the vehicle is weighed again, the weighing clerk can quickly retrieve the vehicle number by only entering part of the number.

6. Information pre-storage function. Common information such as goods names, receiving units, shipping units, unit prices, volume conversion factors, impurity deduction ratios, and quick input codes can be pre-stored. By simply calling one item, relevant information can be quickly read, greatly facilitating the operation of weighers.

7. Black box function. It can automatically record the loading time, unloading time, and current weight of vehicles that pass through the scale platform without any computer operation by the weighing clerk, providing reference data for management personnel.

8. Tare weight tracking. When the tare weight fluctuation of the same vehicle exceeds a certain set range, the software does not allow weighing; 9. Manual data supplementation. In special circumstances, such as temporary power outages, data can be supplemented by operators authorized by leaders with corresponding permissions to ensure the integrity and uniformity of data.

10. Data maintenance records. Only authorized personnel can modify information other than weight data. After modification, the system automatically generates a modification record for future reference, ensuring data security and preventing accidents.

11. Versatile query and statistics. With versatile query and statistics functions, users can perform query, statistics, and summarization based on any condition.

12. Automatic data backup, supporting data import and export. Regular backups can be performed to ensure data security, and data can also be exported to Excel for other forms of use.

13. Data stabilization function. It allows for the setting of a data stabilization time, during which the weight cannot be read to prevent errors caused by excessive scale division values and vehicle vibrations.

14. Data precision processing function. Based on the specific needs of the user, different settings can be made for the precision (number of decimal places retained) and processing methods (rounding down, rounding up, rounding to the nearest) of data such as entry, exit, tare weight, gross weight, and amount.

15. Customize data weigh slips and reports. Not only are multiple print weigh slip formats and report formats available, but users can also design or customize their own according to their specific needs;

16. The weight note supports printing barcodes, QR codes, manufacturer trademarks, weighing photos, and weighing data on the same sheet;

17. The weighing interface can be switched, and suitable weighing interfaces and logical relationships between various fields can be designed according to user needs, achieving the goal of meeting user requirements without changing the code;

18. When there is no broadband available at the weighing site, data can be transmitted back to headquarters via the Hengqibao wireless adapter

19. Support four-channel video weighing and capture, and add watermarks of information such as vehicle number, cargo name, and unit to the photos for preservation