Contact Us

![]() Home Page > Product Center > Industrial Scale Series > Electronic belt scale > ICS-14A electronic belt scale

Home Page > Product Center > Industrial Scale Series > Electronic belt scale > ICS-14A electronic belt scale

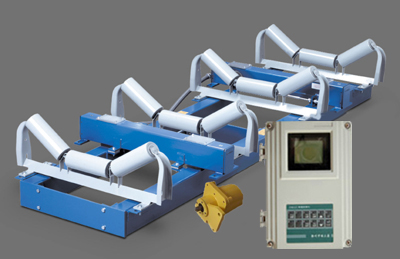

System Composition

The ICS-14A electronic belt scale consists of four parts: ICS-14A weighing bridge, weighing sensor, 60-12C speed sensor and speed roller, and 2001 weighing controller. .

Weighing bridge

The ICS-14 weighing bridge consists of four sets of weighing rollers, a fully floating structure, and no ear pivot points or moving parts. Adopting a rectangular steel pipe design, the entire weighing bridge has sufficient rigidity and small self weight, and the external dust accumulation area is minimized. High precision strain gauge sensors are installed in the tension area to reduce nonlinear errors and ensure the stability of the entire system, with minimal maintenance. There are four pull type weighing sensors suspended from two crossbeams to provide support for the symmetrical weighing bridge. The weighing bridge is a unit component structure that can be easily and quickly installed on site, requiring only eight bolts for installation and fixation.

load cell

The ICS-14 series electronic belt scales all use pull type electronic strain gauges. The main technical indicators are as follows:

◇ Shell: "S" type sealed protection

◇ Nonlinear:<0.03% FS

◇ Non repeatability:<0.01% FS

◇ Creep:<0.02% FS

◇ Zero point output: ± 1%

At maximum flow rate, the displacement of the force application point of the sensor elastic body shall not exceed 0.2mm

◇ Temperature sensitivity: Interval: 0.0008% FS/OF

Zero point: 0.0015% FS/OF

◇ Lag error: 0.02%

Sensitivity error: ± 0.1%

◇ Overload capacity: 150% of sensor capacity

Speed sensors 60-12C, 60-12B

The speed sensor is installed on the tail drum, large-diameter drum or speed roller, and the speed roller/roller is installed on the upper surface of the return belt, eliminating the impact of belt slippage. The speed sensor is a digital brushless pulse generator. When the belt is running, the speed sensor emits a series of speed pulses, each pulse representing a unit length of the belt travel. The pulse frequency is proportional to the belt speed.

2001 Weighing Control Instrument

Using a 32-bit CPU and a 24 bit A/D converter, it speeds up operation and improves measurement accuracy;

All data from the belt scale is displayed on a high brightness four line vacuum fluorescent screen;

The menu style panel operation mode conforms to people's computer operation habits;

When the data related to the belt scale is changed, the original data can be retained for querying to reduce human errors;

◆ Provide multi-level password protection to facilitate different users; Provide linear compensation to ensure the same accuracy of the belt scale between 25% and 100% of the rated load;

◆ Optional analog output for displaying material flow, weight, or speed;

◆ Optional analog output delay for practical control use;

◆ Optional analog input/output board (one or two voltage and current input/output) for control or compensation purposes;

◆ Optional RS-232/RS-485 communication board, which allows you to choose one of the two modes from the hardware settings;

The 2000 series instruments include the 2001 and 2105 models for users to choose from;

201 type weighing instrument

The monitor is a dual screen digital display, with cumulative flow displayed on the upper screen and instantaneous flow displayed on the lower screen;

The input and output of numbers are done using buttons and are called up in the form of instruction codes, for example: 01P represents the zero point value;

Remote counting can be done in two ways: contact and non-contact. When there is no contact, the output is a DC 24V signal;

The optional communication board is used for upper computer communication, and the communication method is RS-485 standard port;

◆ Optional current output board, outputting standard 0-20mA or 4-20mA signals;

◆ Optional printing expansion board, output interface can be connected to MP or PP series parallel port printers.