Contact Us

![]() Home Page > Product Center > Industrial Scale Series > Electronic belt scale > ICS-17B Electronic Belt Weigher

Home Page > Product Center > Industrial Scale Series > Electronic belt scale > ICS-17B Electronic Belt Weigher

Detailed introduction

The ICS-17B electronic belt scale, with a dynamic cumulative error of less than ±0.50%, is suitable for weighing process control in industrial enterprises, such as detecting production volume, controlling quantitative loading of products, and monitoring inventory. It provides important data information for factory automation control and modern management.

System composition

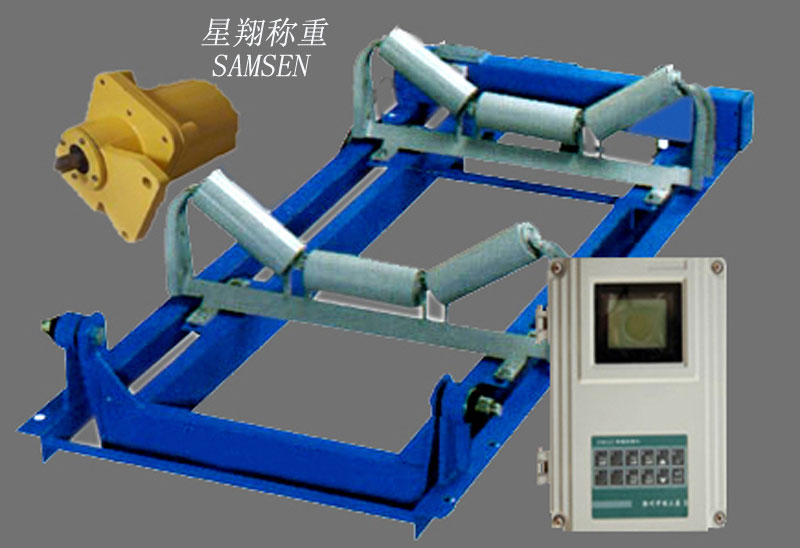

The ICS-17B electronic belt scale consists of four parts: the ICS-17B weighing bridge, the weighing sensor, the 60-12C speed sensor and speed measurement roller, and the SS2001 weighing controller.

Weighing bridge

The ICS-17B weighing bridge frame is equipped with two sets of idlers on the double lever, utilizing two tension sensors for intermediate support, and frictionless trunnion supports on the outer side. This effectively mitigates the impact of eccentric loading on accuracy. This enclosed design provides shock resistance, moisture resistance, corrosion resistance, and prevents material buildup, thus eliminating issues associated with the use of knife edge devices and bearing devices in harsh environments. The main beam of the weighing bridge frame is constructed with rectangular steel tubes, ensuring sufficient rigidity, minimal self-weight, and minimizing external dust accumulation. To ensure the stability of the entire system, high-precision resistance strain gauge sensors are installed at the tensioned areas to reduce nonlinear errors.

The ICS-17B weighing bridge can be directly installed within various belt conveyor frames of different widths, positioned between the upper and lower belts, without occupying vertical space. It is a factory-assembled unit that can be quickly and easily installed and calibrated. This weighing bridge is suitable for belt widths ranging from 400mm to 2000mm.

Weighing sensor

The ICS-17B series electronic belt scales all adopt pull-type electronic strain gauge weighing sensors.

The main technical indicators are as follows:

◇ Shell: "S" type sealing protection

◇ Non-linearity: <0.03%FS

◇ Non-repeatability: <0.01%FS

◇ Creep: <0.02%FS

◇ Zero output: ±1%

◇ At maximum flow rate, the displacement of the force application point of the sensor elastomer is not greater than 0.2mm

◇ Temperature sensitivity: Interval: 0.0008%FS/oF

Zero point: 0.0015%FS/oF

◇ Hysteresis error: 0.02%

◇ Sensitivity error: ±0.1%

◇ Overload capacity: 150% of sensor capacity

Speed measurement sensors 60-12C, 60-12B

The speed sensor is installed on the tail roller, large diameter roller for speed measurement, or speed measuring roller. The speed measuring roller/roller is installed on the upper surface of the return belt, eliminating the impact of belt slippage. The speed sensor is a digital brushless pulse generator. When the belt runs, the speed sensor emits a series of speed pulses, with each pulse representing a unit length of the belt's travel. The pulse frequency is directly proportional to the belt speed.

The shell is made of cast aluminum, suitable for outdoor working environments

The AC pulse generator does not require adjustment or replacement of carbon brushes

Brushless AC pulse generator, no adjustment, calibration, and maintenance required

The latest soft connection technology ensures speed measurement accuracy more effectively and significantly prolongs the service life of the equipment

SS2001 weighing control instrument

◆ The adoption of a 32-bit CPU and a 24-bit A/D accelerates the operation speed and enhances the measurement accuracy;

◆ All data of the belt scale are displayed on a high-brightness four-line vacuum fluorescent screen;

◆ Menu-driven panel operation mode, conforming to people's computer operation habits;

◆ When relevant data of the belt weigher is changed, the original data can be retained for querying to reduce human errors;

◆ Provides multi-level password protection to facilitate different users; provides linear compensation to ensure the belt scale maintains the same accuracy from 25% to 100% of its rated load;

◆ Optional analog output for material flow, weight, or speed display;

◆ Optional analog output delay for practical control applications;

◆ Optional analog input and output board (one or two channels of voltage and current input and output) for control or compensation purposes;

◆ An optional RS-232/RS-485 communication board is available, allowing you to choose one of the two modes through this hardware setting;

◆ The 2000 series instruments include models 2001 and 2105 for users to choose from;

SS201 weighing instrument

◆ The display is a dual-screen digital display, with the upper screen showing cumulative quantity and the lower screen showing instantaneous flow rate;

◆ Digital input and output are controlled through buttons, invoked in the form of command codes. For example, 01P represents the zero point value;

◆ Remote counting can be achieved through two methods: contact and contactless. When using contactless method, the output is a DC 24V signal;

◆ The optional communication board is used for communication with the host computer, and the communication mode is RS-485 standard port;

◆ Optional current output board, with output as standard 0-20mA or 4-20mA signal;

◆ Optional print expansion board, with output interface compatible with mp or pp series parallel port printers.