Contact Us

![]() Home Page > Product Center > Industrial Scale Series > Ingredient scale

Home Page > Product Center > Industrial Scale Series > Ingredient scale

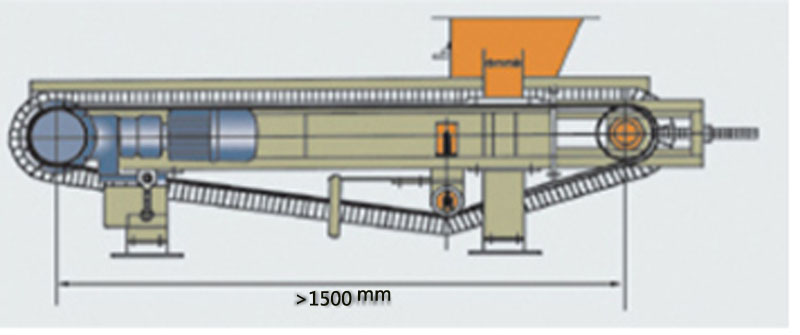

This feeding method is also known as pre feeding control. A star shaped feeder is installed above the feeding hopper. When the quantitative feeder feeds at low speed, the star shaped feeder runs intermittently to fill the feeding hopper with materials. When feeding at high speed with a quantitative feeder, the star feeder and the quantitative feeder operate synchronously and continuously.

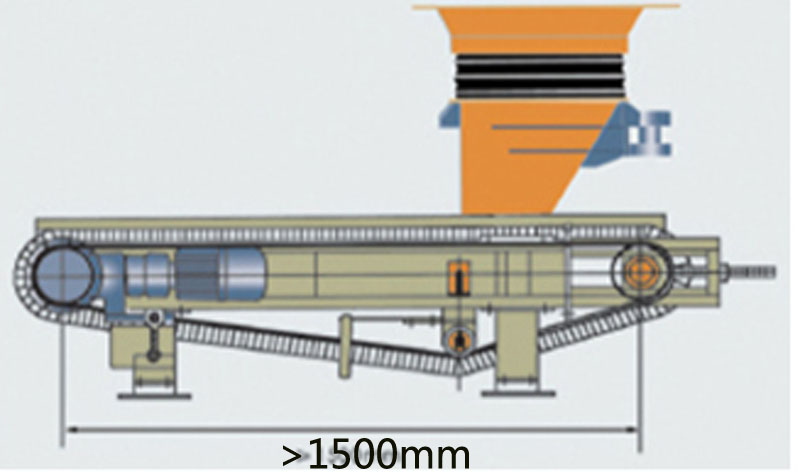

The settling section integrated with the feeding hopper ensures that the material becomes dense and does not flow, and then enters the weighing section, so that the material passing through the weighing section does not move relative to each other.

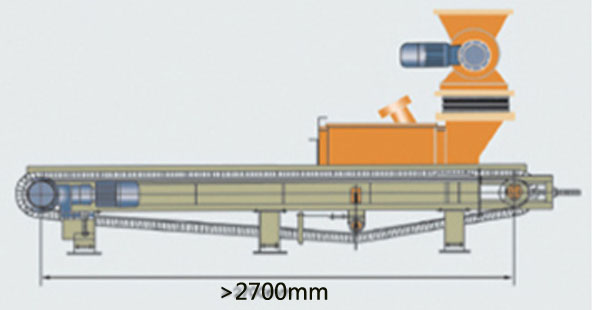

The upper flange of the feeding hopper is connected to the silo, and the lower end of the flange is connected to a soft rubber sleeve. The rubber sleeve faces downwards to form a steel feeding hopper, which is equipped with vibration components. When the quantitative feeder is running, the vibrating components work simultaneously.

Selection Table